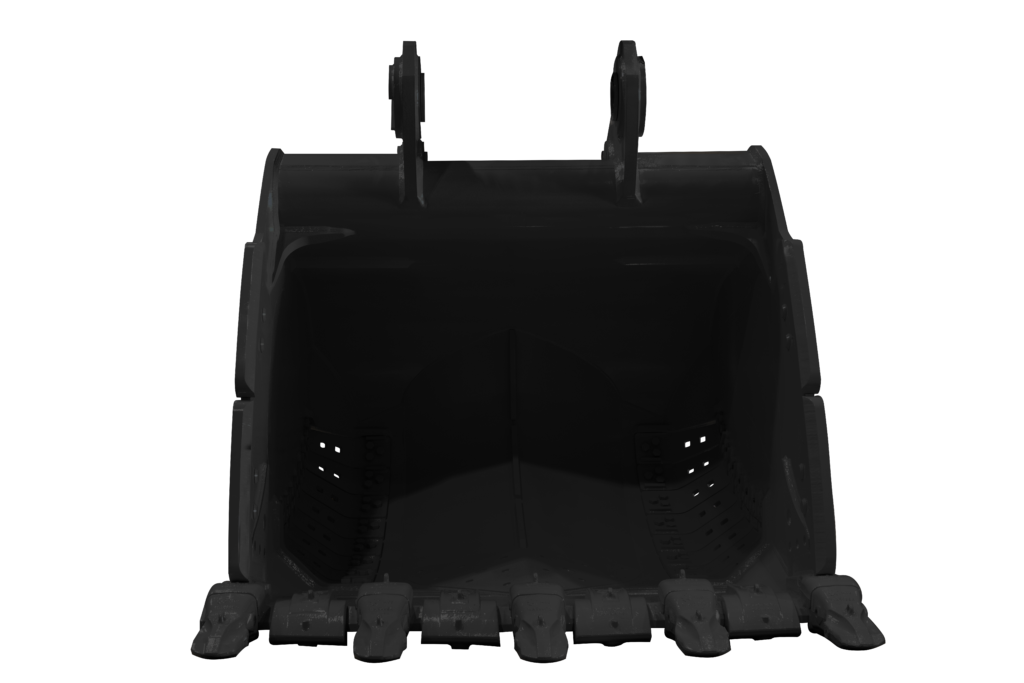

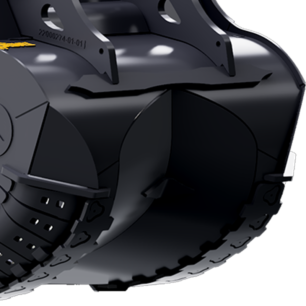

AMI XMOR® BHC Mining Bucket

XMOR® BHC buckets target large-size excavators where increased productivity in digging adds value to the process. XMOR® BHC buckets have the necessary strength for tearing out blast footings, loading trucks and crushers with blasted rock and other heavy-duty operations such as bulk earthworks and coal stripping. The reduced weight allows for more payload without increasing suspended load.

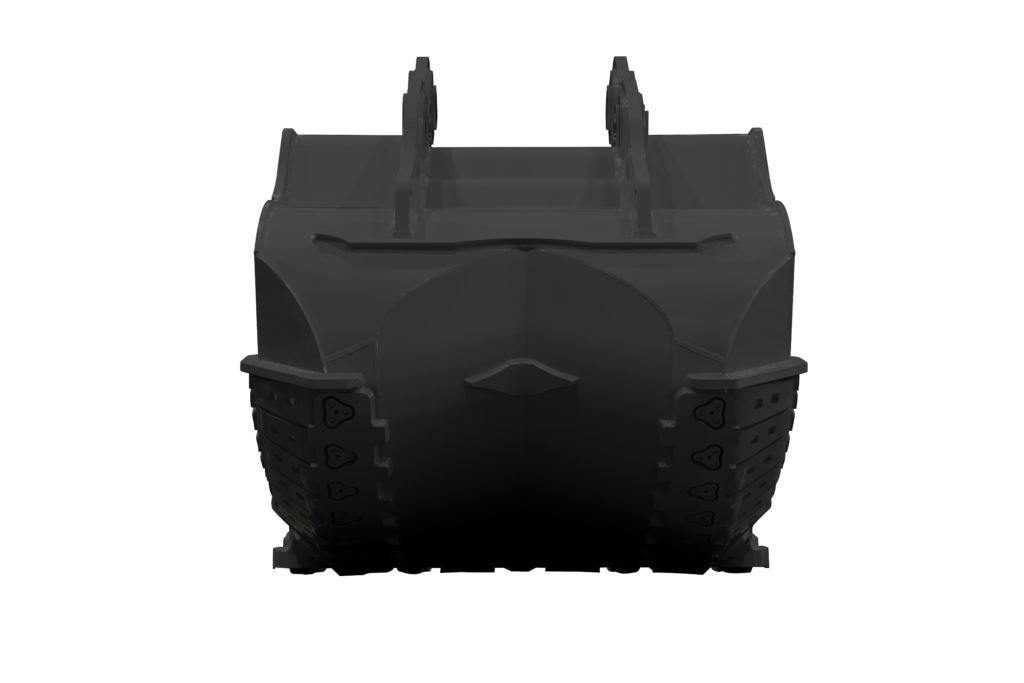

Structural Integrity

Teardrop-shaped Head Beam provides structural integrity and allows the main bucket to be built separately from the shell.

Built Hardox® Strong

Hardox® 450 and Hardox® 500 Tuf in the design allows for reduced plate thickness.

Reduce Maintenance and Downtime

Being mechanically attached, the bolt-on heel shrouds reduce service maintenance time as well as reduce steel overlap for a lighter bucket.

Specially Designed Inverted Keel

The Inverted Keel is a proven and unique XMOR® feature serving the dual purpose of distributing the material smoothly inside the bucket and keeping the external plate away from the material, thus reducing wear.

SPECIFICATIONS - EXCAVATOR

| FastTrack | Category | Model | Machine Class | Width | Weight | Capacity |

|---|---|---|---|---|---|---|

| 750 | BHC100E92 | 140,000 - 160,000 lbs. | 92 " | 15000 lbs | 9 yd³ |

AMI’s Fast Track Program features a wide selection of high-volume products that can be manufactured and shipped in a shorter time period with no compromise in quality and at no extra charge.

AMI’s Fast Track Program features a wide selection of high-volume products that can be manufactured and shipped in a shorter time period with no compromise in quality and at no extra charge.