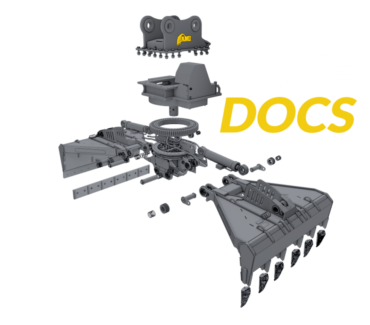

Graptor® Bucket Powered by RAMCAM®

When you need to pick up large, heavy objects, grab bucketful’s of debris or demolish a building, discover a new reality on grip with AMI Attachments’ Graptor® Powered by RAMCAM®. The Graptor® powered by RAMCAM® works using hydraulic cylinders which are fully enclosed and fully protected from the elements. The built-in rotary thumb gives operators improved flexibility and precision by maintaining constant grip on the load throughout the bucket’s entire rotation – putting out the most torque in the most compact design - making the Graptor® Powered by RAMCAM® a powerful tool that keeps a tight handle on heavy, bulky loads.

RAMCAM® Technology

RAMCAM® is a revolutionary new drivetrain that allows for mechanical rotation using hydraulic cylinders enclosed within a protective casing. Patent Pending.

Fully Enclosed Hydraulic Cylinders

Ingeniously designed, the RAMCAM® drivetrain efficiently transfers energy from standard hydraulic cylinders, through a splined camshaft and into the Graptor® thumb for a tight grip on every load. And with RAMCAM® completely enclosed, all components are fully protected at all times.

Constant Grip

Confidently handle heavy, awkward loads with the superior grip of the Graptor® Bucket Powered by RAMCAM®. For demolition work, the Graptor® strongly grips the load and holds it securely throughout the full rotation of the bucket, all the way to roll out.

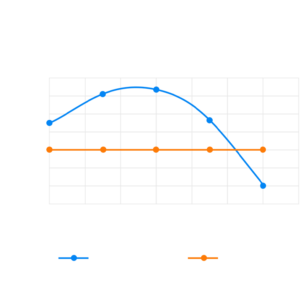

Maximized Gripping Strength

With the increased force at mid-stroke of the hydraulic cylinders, RAMCAM® provides more grip of heavy objects.

Hardox® 500 Tuf Outer Shell

The outer shell is comprised of Hardox® 500TUF wear plate for ultimate wear protection that eliminates the need for heavy wear bars.

Increased Crushing Force

Providing greater torque, RAMCAM® delivers up to 84% more crushing force than the previous Graptor®, for more ripping, biting and demolishing that's reliable and durable.

Grease Bank

With all the grease points now protected, the Graptor® powered by RAMCAM® features a grease bank for simple and routine maintenance.

Heavy Duty Construction

Aggressive serrated side bars, made using Hardox® 450 wear plate are welded in place provide extra grip.

Featured Videos

Profile On Professionals – East Coast Demolition

Here's why East Coast Abatement and Demolition uses the AMI Attachments® Graptor® Bucket Powered by RAMCAM™. "...We were looking for a bucket and thumb combo that was self-contained and protected from the extreme conditions that we put it in...You get more rotation out of it than any other bucket and thumb combo that you can get in the market." Learn more: https://www.amiattachments.com/product/graptor-bucket-powered-by-ramcam/

Specifications - Excavator

| FastTrack | Category | Model | Machine Class | Width | Capacity | Teeth | Grapple Tines | Weight |

|---|---|---|---|---|---|---|---|---|

| 130 | GRHDRC2433E38 | 24,000 - 33,000 lbs | 38 " | 0.690 yd³ | 5 | 4 | 2498 lbs | |

| 130 | GRHDRC2433E42 | 24,000 - 33,000 lbs | 42 " | 0.875 yd³ | 5 | 4 | 1955 lbs | |

| 150 | GRHDRC3340E42 | 33,000 - 45,000 lbs | 42 " | 0.908 yd³ | 5 | 4 | 2689 lbs | |

| 200 | GRHDRC4045E42 | 45,000 - 55,000 lbs | 42 " | 1.060 yd³ | 5 | 4 | 3515 lbs | |

| 200 | GRHDRC4045E48 | 45,000 - 55,000 lbs | 48 " | 1.235 yd³ | 5 | 4 | 3670 lbs | |

| 250 | GRHDRC4560E48 | 55,000 - 65,000 lbs | 48 " | 1.378 yd³ | 5 | 4 | 4210 lbs | |

| 250 | GRHDRC4560E54 | 55,000 - 65,000 lbs | 54 " | 1.573 yd³ | 5 | 4 | 4402 lbs | |

| 300 | GRHDRC6080E54 | 65,000 - 90,000 lbs | 54 " | 2.201 yd³ | 5 | 4 | 6891 lbs | |

| 300 | GRHDRC6080E60 | 65,000 - 90,000 lbs | 60 " | 2.479 yd³ | 6 | 5 | 7307 lbs | |

| 400 | GRHDRC80100E60 | 90,000 - 115,000 lbs | 60 " | 2.479 yd³ | 6 | 5 | 7307 lbs | |

| 650 | GRHDRC120140E72 | 120,000 - 140,000 lbs. | 72 " | 4.733 yd³ | 5 | 4 | 13979 lbs |

AMI’s Fast Track Program features a wide selection of high-volume products that can be manufactured and shipped in a shorter time period with no compromise in quality and at no extra charge.

AMI’s Fast Track Program features a wide selection of high-volume products that can be manufactured and shipped in a shorter time period with no compromise in quality and at no extra charge.