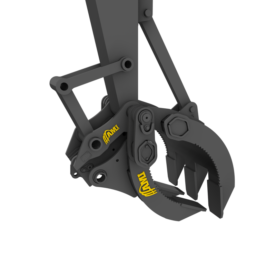

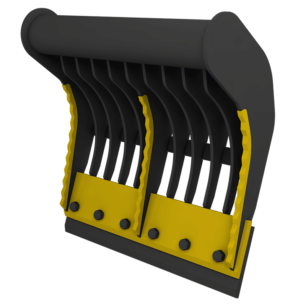

Demolition & Sorting Grapple – Non-Rotating

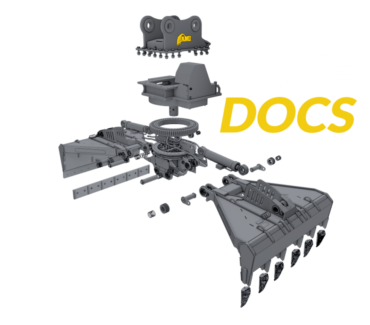

High performance strength meets cutting-edge agility with AMI Attachments’ Extractor - the versatile demolition and sorting grapple capable of taking down buildings, moving large volumes of material, and picking through fine recyclables. Built for strenuous work, the Extractor is made with Hardox Wear Plates and Strenx steel and moves higher volumes of material using less fuel - cycle after cycle. The Extractor rotates 360 degrees and features flexible jaw operation with edge-to-edge contact, reversible cutting edges, and zero clearance design for maximum productivity.

Edge-To-Edge Contact

The Extractor’s precision edge-to-edge contact makes selecting thin and valuable items incredibly easy.

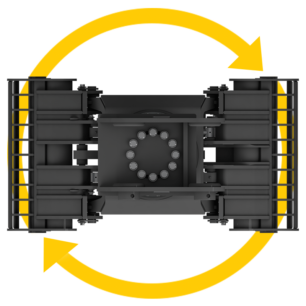

360° Rotation

For exceptional performance and total operator control, the Extractor rotates 360 degrees to position the grapple accurately and move loads quickly.

Hardox Wear Plate

High-wear serrated edges and mounting edges are made with Hardox Wear Plate, an abrasion-resistant steel that can repeatedly withstand the Extractor’s rigorous work.

Vertical Tines

With the Extractor’s zero clearance jaw design, operators can easily retrieve objects tightly positioned against walls and bins with its perfectly vertical jaw opening.