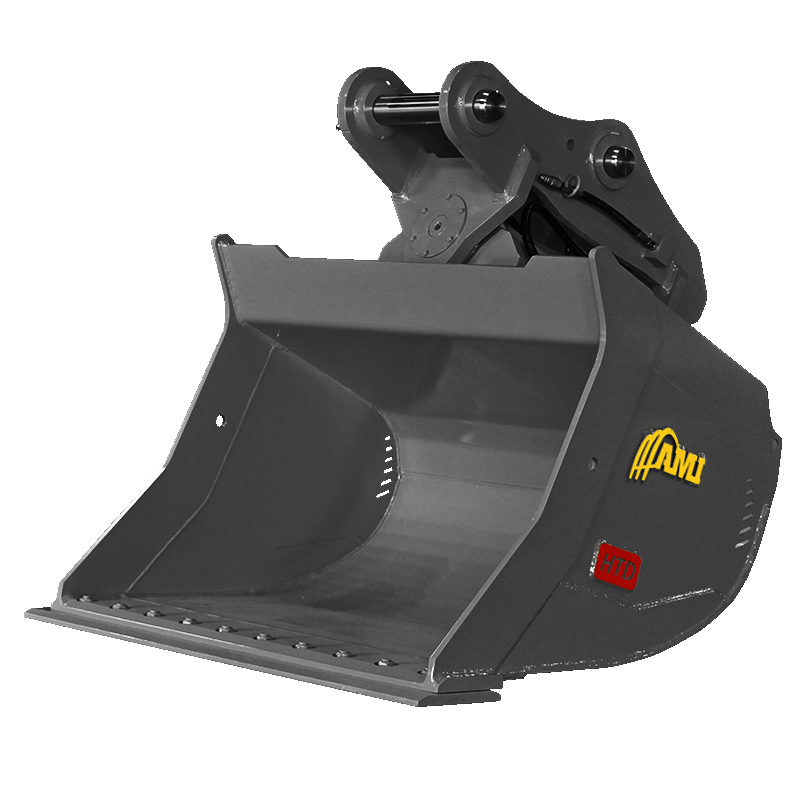

TILT BUCKET Powered by RAMCAM®

AMI Attachment's Tilt Bucket Powered by RAMCAM® - the ultimate heavy-duty attachment designed to conquer any task with ease. This rugged and powerful tilt bucket is built to last, providing reliability in demanding conditions. Equipped with RAMCAM® technology, the hydraulic cylinders are fully protected with minimal hose exposure, reducing damage and downtime. No more broken cylinders from rock obstruction, interference from material build-up, or frozen dirt on bucket's mechanical components. The Tilt Bucket Powered by RAMCAM® is the first Tilt Bucket that’s got every angle covered.

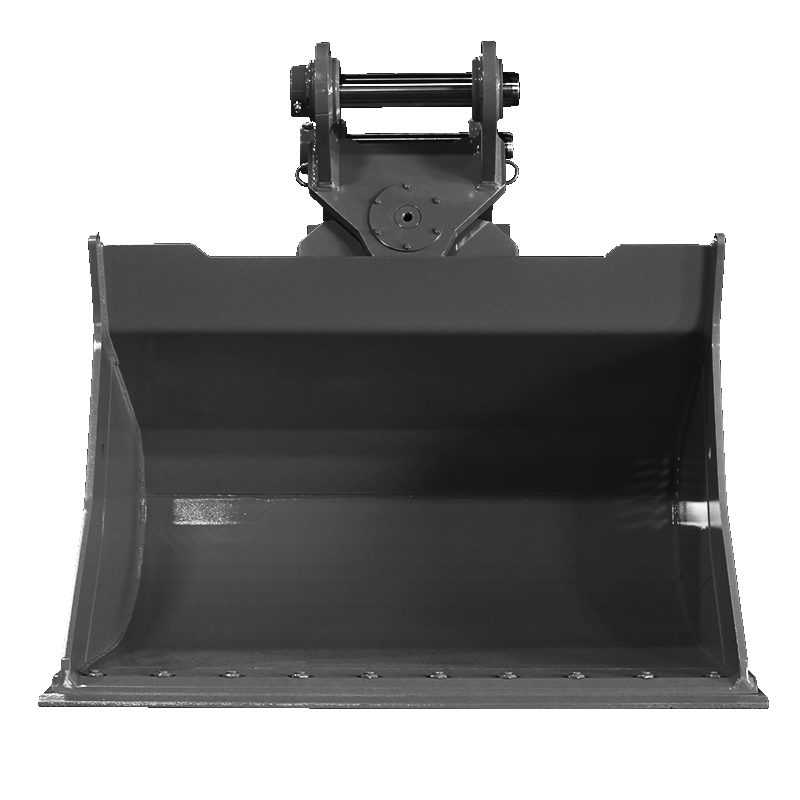

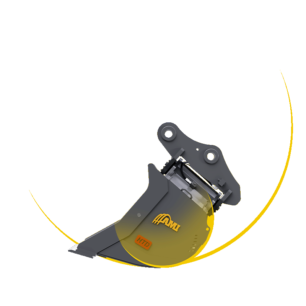

RAMCAM®

RAMCAM® is a revolutionary new drivetrain that allows for mechanical rotation using hydraulic cylinders within a protective casing. Patent Pending.

SPLINED PIN

More than just a pivot point, RAMCAM™ features a splined pin that stays securely in place. As the hydraulic cylinders push against the lobes, the torque is transferred to the splines providing rigidity and strength.

Grease Bank

With all the grease points now protected, the Tilt Bucket powered by RAMCAM™ features a grease bank for simple and routine maintenance.

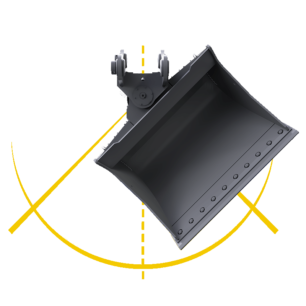

90° Rotation

With 90-degree tilt, the RAMCAM™ drivetrain delivers the same tilt range as AMI Attachments’ conventional tilt bucket.

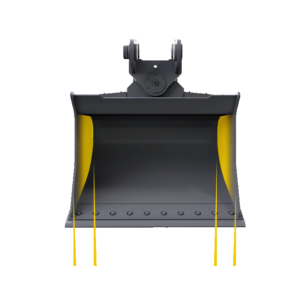

Tapered Sidewalls

Along with a replaceable bolt-on cutting edge, the bucket includes tapered sidewalls, reducing friction between material and bucket when unloading.

Dual Radius Heel

The heel profile incorporated a dual radius contour, minimizing surface contact while curling.

Specifications - Excavator

| FastTrack | Category | Model | Machine Class | Width | Capacity | Weight |

|---|---|---|---|---|---|---|

| 130 | HTDRC2433E54 | 24,000 - 33,000 lbs | 54 " | 0.765 yd³ | 1410 lbs | |

| 130 | HTDRC2433E60 | 24,000 - 33,000 lbs | 60 " | 0.860 yd³ | 1505 lbs | |

| 150 | HTDRC3340E54 | 33,000 - 45,000 lbs | 54 " | 0.688 yd³ | 1690 lbs | |

| 150 | HTDRC3340E60 | 33,000 - 45,000 lbs | 60 " | 0.750 yd³ | 1790 lbs | |

| 200 | HTDRC4045E60 | 45,000 - 55,000 lbs | 60 " | 1.095 yd³ | 2445 lbs | |

| 200 | HTDRC4045E66 | 45,000 - 55,000 lbs | 66 " | 1.220 yd³ | 2570 lbs | |

| 200 | HTDRC4045E72 | 45,000 - 55,000 lbs | 72 " | 1.345 yd³ | 2710 lbs | |

| 250 | HTDRC4560E60 | 55,000 - 65,000 lbs | 60 " | 1.413 yd³ | 2975 lbs | |

| 250 | HTDRC4560E66 | 55,000 - 65,000 lbs | 66 " | 1.575 yd³ | 3090 lbs | |

| 250 | HTDRC4560E72 | 55,000 - 65,000 lbs | 72 " | 1.735 yd³ | 3340 lbs | |

| 300 | HTDRC6080E66 | 65,000 - 90,000 lbs | 66 " | 1.825 yd³ | 4075 lbs | |

| 300 | HTDRC6080E72 | 65,000 - 90,000 lbs | 72 " | 2.015 yd³ | 4430 lbs | |

| 300 | HTDRC6080E84 | 65,000 - 90,000 lbs | 84 " | 2.390 yd³ | 4880 lbs | |

| 400 | HTDRC80100E78 | 90,000 - 115,000 lbs | 78 " | 2.660 yd³ | 5935 lbs | |

| 400 | HTDRC80100E84 | 90,000 - 115,000 lbs | 84 " | 2.880 yd³ | 6170 lbs |

AMI’s Fast Track Program features a wide selection of high-volume products that can be manufactured and shipped in a shorter time period with no compromise in quality and at no extra charge.

AMI’s Fast Track Program features a wide selection of high-volume products that can be manufactured and shipped in a shorter time period with no compromise in quality and at no extra charge.