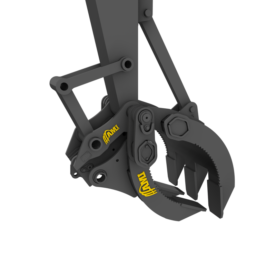

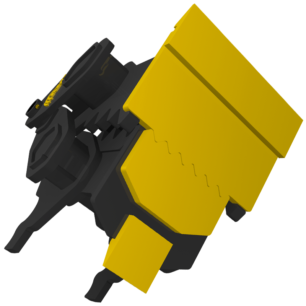

Concrete Pulverizer

Standing strong in the concrete jungle is the AMI Kraken Concrete Pulverizer – the fast and simple way to crush concrete. Built for durable, long-term use, the Kraken Concrete Pulverizer is fully mechanical, made with Hardox wear points and requires no auxiliary hydraulics. Available for use with a coupler or direct pin-on, the Kraken Concrete Pulverizer is ready to claim new ground. Optional rebar shear available.

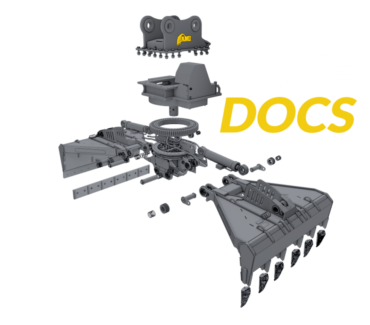

Break Point

By using longer teeth in the centre, breaking force is maximized at initial crush by concentrating pressure across fewer points. After first penetration, the secondary jaw teeth crumble the concrete into manageable pieces. Made from Hardox 500 steel, the replaceable jaw teeth have excellent hardwearing quality and are welded into place.

Flow-Thru Channels

The Kraken’s 3 over 4 jaw configuration provides crushing strength that pushes the broken material through the jaws for efficient productivity.

Oversize Hex Torque Tubes

The torque tube’s hexagonal profile is one of the strongest shapes in nature and provides a sturdy core running the width of the pulverizer to prevent twisting and deforming.

Serrated Pinch Plates

Sorting debris and rebar is part of the job and the Hardox 400 steel pinch plates give you the grip and precision you need to pick, hold and carry fine material.

3 Position Bracket

Fine tune your productivity by adjusting the lower jaw’s angle using the three position support bracket.

Optional Rebar Shear

Upgrade with the optional rebar shear, effectively slicing rebar while crushing material. Made with high grade steel, the bolt-on blades are easily replaced.

SPECIFICATIONS - EXCAVATOR

| FastTrack | Category | Model | Machine Class | Description | Weight |

|---|---|---|---|---|---|

| 130 | PU243334 | 24,000 - 33,000 lbs | 3 Over 4 Jaw Configuration | 2000 lbs | |

| 150 | PU334034 | 33,000 - 45,000 lbs | 3 Over 4 Jaw Configuration | 2250 lbs | |

| 200 | PU404534 | 45,000 - 55,000 lbs | 3 Over 4 Jaw Configuration | 2520 lbs | |

| 200 | PU404545 | 45,000 - 55,000 lbs | 4 Over 5 Jaw Configuration | 2720 lbs | |

| 250 | PU456034 | 55,000 - 65,000 lbs | 3 Over 4 Jaw Configuration | 3300 lbs | |

| 250 | PU456045 | 55,000 - 65,000 lbs | 4 Over 5 Jaw Configuration | 3560 lbs | |

| 300 | PU608034 | 65,000 - 90,000 lbs | 3 Over 4 Jaw Configuration | 4350 lbs | |

| 300 | PU608045 | 65,000 - 90,000 lbs | 4 Over 5 Jaw Configuration | 4655 lbs | |

| 400 | PU8010034 | 90,000 - 115,000 lbs | 3 Over 4 Jaw Configuartion | 5980 lbs | |

| 400 | PU8010045 | 90,000 - 115,000 lbs | 4 Over 5 Jaw Configuartion | 6390 lbs |

AMI’s Fast Track Program features a wide selection of high-volume products that can be manufactured and shipped in a shorter time period with no compromise in quality and at no extra charge.

AMI’s Fast Track Program features a wide selection of high-volume products that can be manufactured and shipped in a shorter time period with no compromise in quality and at no extra charge.