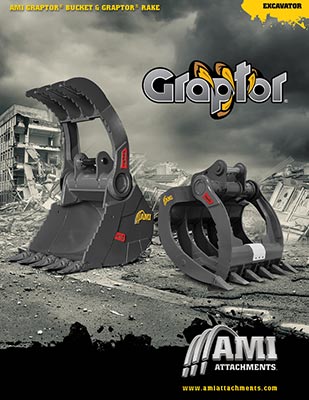

Demolition Graptor® Bucket Powered by RAMCAM®

When it’s demo day, look no further than the Graptor® Demolition Bucket powered by RAMCAM™ to take on the task at hand! The Graptor® Demolition Bucket powered by RAMCAM™ combines the versatility and precision of the Graptor® Bucket with an extra level of strength for demolition applications. This bucket features a Hardox® 500 wear package and replaceable thumb for increased wear performance. For increased durability, replaceable weld-on teeth come standard on the bucket. Weld-on adaptors plus teeth are available as an alternate option. US patents 10,774,498 and 10,774,501.

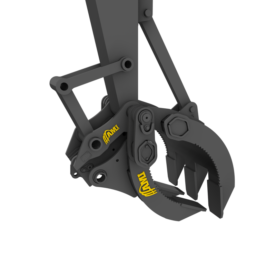

RAMCAM™ Technology

RAMCAM™ is a revolutionary new drivetrain that allows for mechanical rotation using hydraulic cylinders enclosed within a protective casing. Patent Pending.

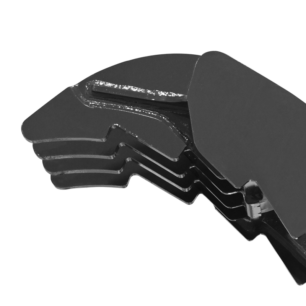

Fully Enclosed Hydraulic Cylinders

Ingeniously designed, the RAMCAM™ drivetrain efficiently transfers energy from standard hydraulic cylinders, through a splined camshaft and into the Graptor® thumb for a tight grip on every load. And with RAMCAM™ completely enclosed, all components are fully protected at all times.

Added Wear Plates

CONSTANT GRIP

Confidently handle heavy, awkward loads with the superior grip of the Demolition Graptor® Bucket Powered by RAMCAM™. For demolition work, the Demolition Graptor® strongly grips the load and holds it securely throughout the full rotation of the bucket, all the way to roll out.

Added Hardox® Wear Plate

Replaceable Weld-On Teeth

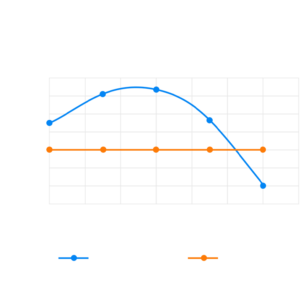

Increased Crushing Force

Providing greater torque, RAMCAM™ delivers up to 84% more crushing force than the previous Demlition Graptor®, for more ripping, biting and demolishing that's reliable and durable.

HEAVY DUTY CONSTRUCTION

Aggressive serrated side bars, made using Hardox® 450 wear plate are welded in place provide extra grip.

Option - Replaceable Teeth on Tine

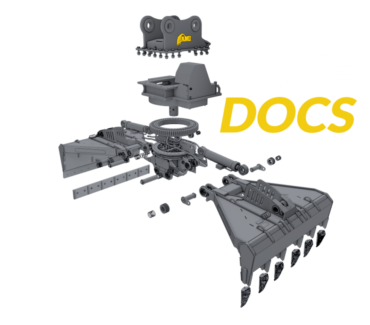

Specifications - Excavator

| FastTrack | Category | Model | Machine Class | Width | Capacity | Teeth | Weight |

|---|---|---|---|---|---|---|---|

| 150 | GRDM3340E30 | 33,000 - 45,000 lbs | 30 " | 0.530 yd³ | 4 | WOR | |

|

150 | GRDM3340E36 | 33,000 - 45,000 lbs | 36 " | 0.815 yd³ | 5 | WOR |

| 150 | GRDM3340E42 | 33,000 - 45,000 lbs | 42 " | 0.975 yd³ | 5 | WOR | |

| 200 | GRDM4045E36 | 45,000 - 55,000 lbs | 36 " | 0.945 yd³ | 5 | WOR | |

|

200 | GRDM4045E42 | 45,000 - 55,000 lbs | 42 " | 1.060 yd³ | 5 | 3565 lbs |

| 200 | GRDM4045E48 | 45,000 - 55,000 lbs | 48 " | 1.235 yd³ | 5 | WOR | |

| 250 | GRDM4560E36 | 55,000 - 65,000 lbs | 36 " | 0.985 yd³ | 4 | 3265 lbs | |

| 250 | GRDM4560E42 | 55,000 - 65,000 lbs | 42 " | 1.190 yd³ | 5 | 3565 lbs | |

|

250 | GRDM4560E48 | 55,000 - 65,000 lbs | 48 " | 1.375 yd³ | 5 | 4120 lbs |

| 250 | GRDM4560E54 | 55,000 - 65,000 lbs | 54 " | 1.575 yd³ | 5 | 4165 lbs | |

| 300 | GRDM6080E48 | 65,000 - 90,000 lbs | 48 " | 1.855 yd³ | 5 | 4915 lbs | |

|

300 | GRDM6080E54 | 65,000 - 90,000 lbs | 54 " | 2.125 yd³ | 5 | 5430 lbs |

AMI’s Fast Track Program features a wide selection of high-volume products that can be manufactured and shipped in a shorter time period with no compromise in quality and at no extra charge.

AMI’s Fast Track Program features a wide selection of high-volume products that can be manufactured and shipped in a shorter time period with no compromise in quality and at no extra charge.